To the sounds of African gospel music, stitchers seated at sewing machines are attaching sleeves, pockets and zippers onto thick green and blue garments piling up on tables around the room.

Working in a 40,000-square-foot, light-infused factory inside Westbrook’s Dana Warp Mill, they’re making hoodies, jackets, T-shirts and custom apparel for American Roots, a clothing manufacturer founded in 2015. It sells in bulk to unions and business organizations.

Stitchers work in teams, supervised by two floor leads who started as stitchers themselves.

“We make sure the work is flowing nicely, and we check also the quality,” Makenga Tshibwabwa, originally from the Democratic Republic of the Congo, explains over the steady hum of sewing machines. Ragad Abo Aljaaz, who hails from Iraq, laughs about how at home “I call my daughter ‘Matenga’ because I think in the day I say ‘Matenga’ 100 times.”

Both are part of a close-knit community of immigrants representing 10 nationalities in the 75-strong workforce. An American flag hangs on the wall.

“We work as a family,” Tshibwabwa says as colleagues stand for a guided stretching break.

Building a workforce

Ben and Whitney Waxman founded American Roots in 2015, inspired in part by Ben’s mother Dory Waxman, who ran a woolen goods business in Portland. With American Roots, the couple set out to produce high-quality, union-made apparel sourced 100% domestically and rebuild manufacturing in a more just and sustainable way.

Undeterred by the lack of skilled textile workers, they created a workforce trained to sew at a school founded by Dory. Today, the company relies on around two dozen sewers to produce around 2,000 to 3,500 garments a week.

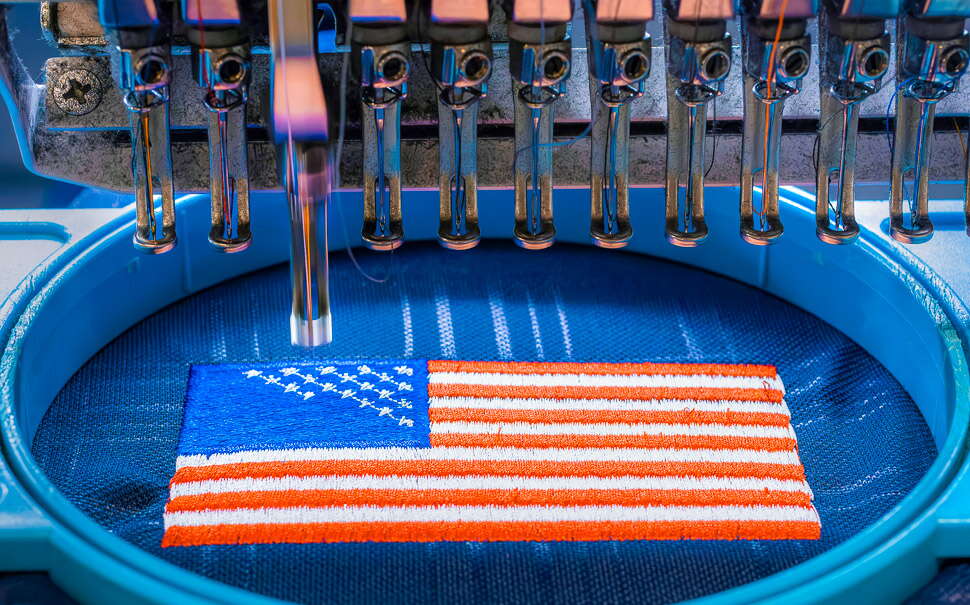

American Roots gets its materials from about a dozen suppliers, using cotton that’s grown in Texas, ginned in Alabama, spun in South Carolina and finished and dyed in North Carolina. The fabric is cut and sewn into garments that are inspected twice before proceeding to stock inventory or for finishing touches like embroidery or screen printing. Defective items that can’t be fixed on the factory floor are donated to local organizations.

Ups and downs

The business has had its challenges, including a $250,000 loss in 2019 from bad fabric and retooling operations during the pandemic.

Now in expansion mode, American Roots aims to soon add another 1,500 square feet for production, boost its sales team in 2026 after tripling the number this year and bring more processes in-house as it did with screen printing a few years ago.

While bricks-and-mortar retail is a longer-term possibility, “we’re very intentional in everything that we do,” Whitney says.

Reflecting on the entrepreneurial roller coaster, Ben says that “what we’ve done is not for the thin-skinned, but it has been the most beautiful, most incredible, hardest thing I’ve ever done in my life.” What’s the payoff? “We make the best sweatshirt in America,” he says.

Ben Waxman and Whitney Reynolds Waxman, founders and owners of American Roots, in Westbrook

Ben Waxman and Whitney Reynolds Waxman, founders and owners of American Roots, in Westbrook